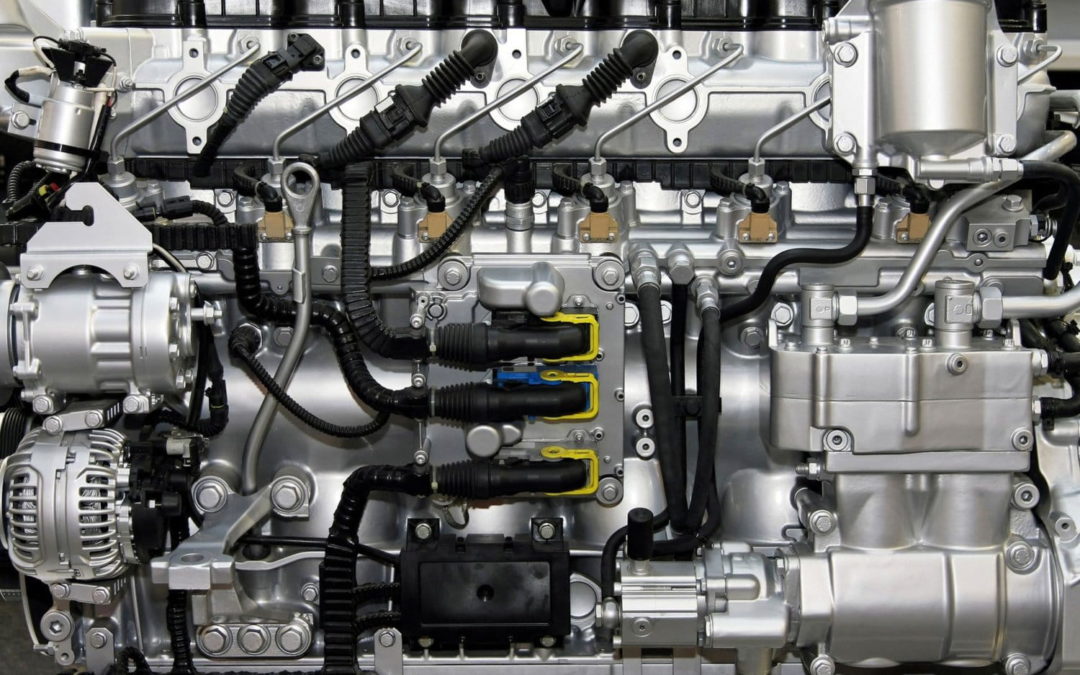

Industrial diesel engines have proven to be efficient and cost-effective by most industrial companies. Now that fuel value is drastically increasing, depending on the demand and supply of the consumers, a cost-effective fuel alternative should meet all your standards and needs.

For you to have in-depth knowledge about the diesel-fueled engine, we will discuss its advantages and the differences between diesel and gasoline engines.

Advantages of Using an Industrial Diesel Engine

When it comes to sound and maintenance, today’s industrial diesel engine has improved compared to the earlier models. With advancements in technology over the years, the diesel engine now operates quietly and does not need support to keep up with its functionality.

- Industrial diesel engines are durable and reliable

- No sparking and fuel issues, low maintenance costs for spark plugs and wires

- Fuel-efficient

- Does not require a higher unit of water-cooled gas to operate

- Longer life than gas units since gas engines burn a lot hotter when compared to diesel engines

Below is the comparison between diesel-fueled engine and gasoline:

Differences between the Diesel and Gasoline Engine

- The industrial diesel is much denser than a gasoline engine, and it has a higher boiling point than water

- Diesel fueled engine is quite costly compared to a gasoline engine, but diesel offers higher energy density than gasoline

- A diesel-powered engine, especially for industrial vehicles, can provide higher mileage; turning it into a perfect option for heavy-duty tasks such as transporting goods and large equipment

- Diesel is more reliable than gasoline engines. Not only does it promote efficiency for industrial tasks, but also for the actual engine itself, which makes it a low-cost maintenance engine.

Both gasoline and diesel have different types of ignition. The gasoline engine uses spark ignition, while diesel utilizes compression. It is a process of combustion that ignites the fuel. When the air is pulled through the engine, and it passes through to a higher heat compression, it creates more elevated temperature to the vehicle’s engine than gasoline. During peak temperature, the engine will ignite depending on how extreme the temperature is.

To start compression, the air and fuel are mixed up together in a diesel engine, and the fuel is pushed to the engine using an injector device. That is why a carburetor is needed for this process. However, for gasoline engines, both fuel and air are mixed together and compressed after.

Why Industrial Diesel is Your Better Option

The diesel engine is famous when used for mechanical equipment and power generators. It is mainly used to provide functionality for locomotives, heavy construction equipment, industrial tasks, and automobiles. Industrial diesel engines are also the most efficient option for mining, forestry, hospitals, telecommunications, agricultural applications, and so on.

With the broad usage of industrial diesel engines, it is true that it can benefit different businesses towards its success. This is the reason why many companies are switching and making a wise decision to replace their old gasoline-fueled machines or vehicles into more efficient diesel-fueled engines.